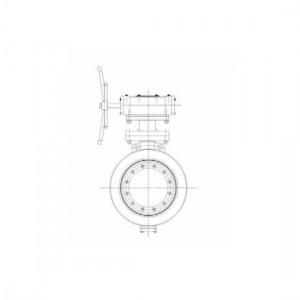

High Performance Wafer Butterfly Valve

Body

• The valve body shall be one piece cast or fabrication.

• The body can be supplied with different types of materials in wafer, lug, or flanged and butt welding end connections to satisfy all installation requirements.

Body Seat

• The valve seat shall be integrated with the body.

• Stellite or stainless steel shall be applied on the seating surfaces of valve body.

• The valve seat is designed for inclined cone to ensure non-rubbing, non-jamming, bi-directional shutoff, and zero leakage.

Technical Specification

| Structural formation | Single eccentric structure/double eccentric structure / three eccentric structure/ variable eccentric structure | |

| Design reference | CJ GB JB | API |

| Driving manner | Hand - operated, worm wheel & worm screw pneumatic operated, Electric - driving | |

| Design standard | GJ/T 216 GB/T 12238 JB/T8527 |

API 609 MSS.SP - 68 |

| Face to face | GB/T 12221 | ASME B16.10 API 609 MSS.SP - 68 |

| Flanged ends | JB/T 79. JB/T 82 BG/T9113 GB/T 17241.6 |

ASME B16.5 ASME B 16.47 |

| Test & inspection | GB/T 13927 JB/T 9092 |

API 598 |

Note: The sizes of valve connecting flange and butt-welding terminas can be designed according to customer's requirement.

Major Parts Material Form

| NO. | Part name | Materials |

| 1 | Body | WCB.CF8 CF8M CF8C CF3 CF3M LCB、QT450-10 |

| 2 | Stem | 12Cr13.20Cr1306Cr18Ni9Ti06Cr18Ni12Mo2Ti |

| 3 | Disc | WCB+F4WCB+Stainless steel composite partsQT450-10+NBR WCB+F6CF8CF8M、QT450-10+EPDM |

| 4 | Packing seat | 20Cr13 |

| 5 | Packing | Graphite |

| 6 | Stuffing cover | WCB.CF8 CF8M |

| 7 | Yoke | WCB.CF8 CF8M CF3 CF3M |

| 8 | Worm device |

Leave Your Message